To ensure correct measurement rotate the vernier around the

rope diameter to ensure the correct size is obtained

| 1 |

Mechanical

damage due to rope movement over sharp edge projection whilst

under load. |

|

|

|

| 2 |

Localised

wear due to abrasion on supporting structure. |

|

|

|

| 3 |

Narrow

path of wear resulting in fatigue fractures, caused by working in

a grossly oversize groove, or over small support rollers. |

|

|

|

| 4 |

Two

parallel paths of broken wires indicative of bending through an

undersize groove in the sheave. |

|

|

|

| 5 |

Severe

wear, associated with high tread pressure. |

|

|

|

| 6 |

Severe

wear in Langs Lay, caused by abrasion. |

|

|

|

| 7 |

Severe

corrosion. |

|

|

|

| 8 |

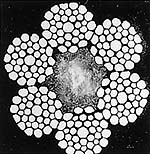

Internal

corrosion whilst external surface shows little evidence of

deterioration. |

|

|

|

| 9 |

Typical

wire fractures as a result of bend fatigue. |

|

|

|

| 10 |

Wire

fractures at the strand, or core interface, as distinct from

‘crown’ fractures. |

|

|

|

| 11 |

Break

up of IWRC resulting from high stress application. |

|

|

|

| 12 |

Looped

wires as a result of torsional imbalance and/or shock loading. |

|

|

|

| 13 |

Typical

example of localised wear and deformation. |

|

|

|

| 14 |

Multi

strand rope ‘bird caged’ due to tors ional imbalance. |

|

|

|

| 15 |

Protrusion

of rope centre resulting from build up of turn. |

|

|

|

| 16 |

Substantial

wear and severe internal corrosion. |

|

|

|